POU COOLER

POU COOLER

Product Description

In industries where precise temperature control is critical, Point-of-Use (POU) Cooler Systems play a vital role in maintaining optimal conditions for processes, storage, and product integrity. These systems are designed to deliver cooled water or fluids at the exact location where they are needed, ensuring efficiency, consistency, and compliance with industry standards.

POU coolers are widely used in the pharmaceutical, food & beverage, chemical, and manufacturing industries, where even slight temperature variations can impact product quality. This article explores the importance, benefits, and applications of POU cooler systems across different sectors.

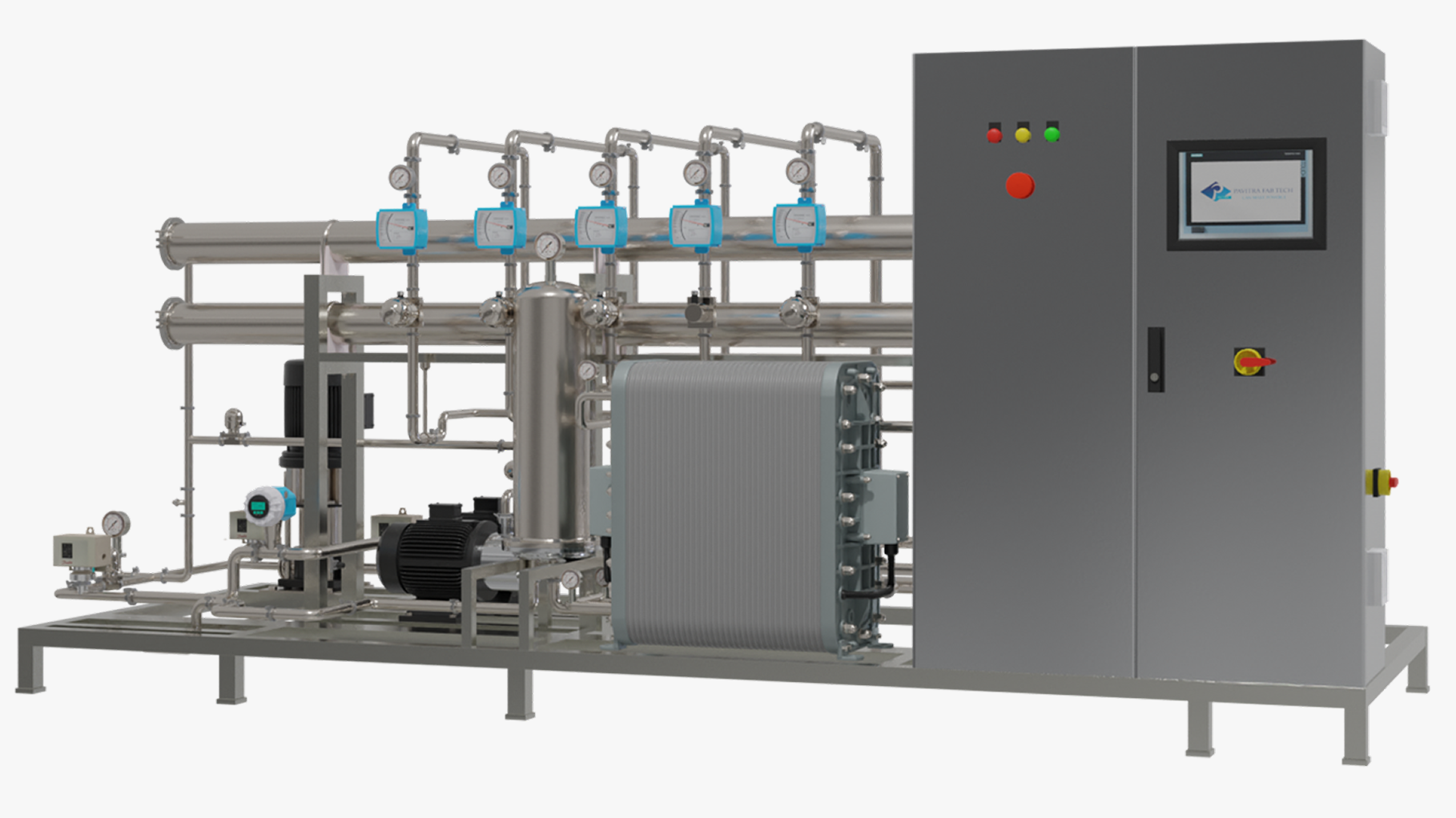

3600 View

Click and drag to rotate the system. Click hotspots to know more

Key Features

Cooling Method

Features:

- Double-tube or shell-and-tube heat exchanger for efficient heat transfer.

- Uses cold water or chilled WFI – as a cooling medium.

- Compact models – Thermoelectric cooling or refrigerant-based systems.

- Adjustable cooling capacity – to match process requirements.

- Energy-efficient – designs to minimize operational costs.

Construction

Features:

- 316L stainless steel – with electropolished internal surfaces for corrosion resistance.

- Hygienic, sanitary design – compliant with ASME BPE standards.

- Sloped, drainable design – with zero dead legs to prevent contamination.

- Modular configurations –for easy integration into existing systems.

- Leak-proof seals and gaskets – for long-term reliability.

Temperature Control

Features:

- Automatic or Manual – coolant flow control for precision.

- Outlet temperature – typically cooled to 20–25°C (customizable)

- Integrated – temperature sensors & digital displays (optional).

- Real-time monitoring – with alarms for deviations.

- PID controllers – for stable and responsive adjustments.

Sterility and Hygiene

Features:

- Compatibility - CIP/SIP.

- Steam-sterilizable – up to 121°C for microbial control.

- Hydrophobic vent filters – to prevent contamination.

- Fully drainable – design to eliminate stagnant fluid.

- FDA & EHEDG-compliant – materials for food/pharma safety.

Connectivity & Automation

Features:

- PLC integration – for seamless process control.

- Remote monitoring – via SCADA or IoT-enabled systems.

- Data logging – for compliance and traceability.

- Quick-connect fittings – for easy maintenance.

- Low-maintenance – design with minimal downtime.

Energy Efficiency & Sustainability

Features:

- Low water consumption – with recirculation options.

- Eco-friendly refrigerants – in refrigerant-based models.

- Heat recovery systems – to repurpose waste energy.

- Variable-speed pumps – to reduce power usage.

- LEAN manufacturing-compatible – for waste reduction.

POU Coolers

Desgined for high thermal efficiency, our SS316L, POU COOLERS are designed to be compact, with electropolished internals and is easy to install

- Higher Thermal Efficiency

- Automated Operation

- Instant Delivery of Water

- Continuous Flow in Main & Subloop

Why This System?

- Precision Cooling: – Ensures consistent temperature control at the point of use, critical for sensitive processes.

- Regulatory Compliance: – Meets GMP, FDA, and ASME BPE standards for hygiene and safety.

- Reduced Contamination Risk: – CIP/SIP and drainable design minimize microbial growth.

- Cost-Effective: – Energy-efficient and low-maintenance, reducing operational expenses.

- Scalable & Adaptable: – Modular design fits diverse industry needs, from pharma to food processing.

- Reliable Performance: – Durable construction and smart monitoring ensure long-term dependability.

Key Features :

Instant Cooled WFI

Delivers instant temperature controlled WFI instantly

Full Drainability

Full drainability on the product side

High Turbulence

Eliminates formation of bio-film inside the tubes

Standards Compliance

Compliance to various standards including ASME-BPE

Projects Executed

Our Portfolio

Schedule a Meeting

Need a customized solution for your industry? Contact us today for expert design and implementation!

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!