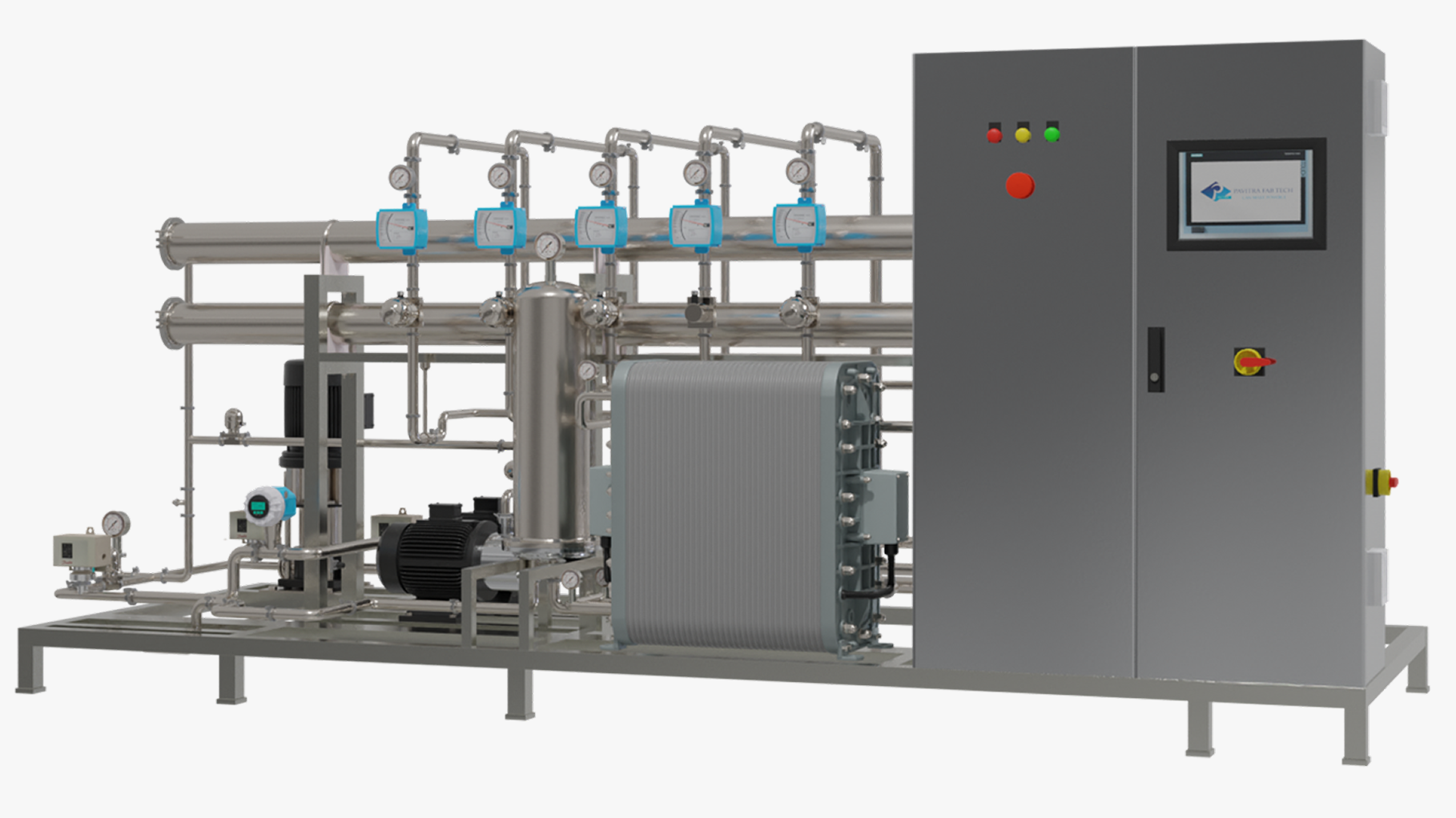

Pre-Treatment System

Designed To Handle Fluctuating Raw Water Quality

Product Description

Engineered for Efficiency, Safety, and Reliability in Variable Raw Water Conditions

Our pre-treatment systems are meticulously designed to ensure uninterrupted performance even under variable raw water conditions.

The goal is to protect sensitive downstream systems—especially Reverse Osmosis and UF membranes—by stabilizing feed water quality and reducing fouling, scaling, and bio-contamination risks.

3600 View

Click and drag to rotate the system. Click hotspots to know more

Key Features

Comprehensive Source Water Analysis

Features:

- Detailed contaminant profiling (TDS, hardness, organics, microbes).

- Customized system design based on water quality data.

- Identifies chlorine, heavy metals, and suspended solids.

- Supports compliance owith EPA, WHO, and industry standards.

- Real-time data logging for performance tracking.

Advanced Disinfection & Bio-Control

Features:

- UV sterilization for effective microbial reduction.

- Chemical dosing (antiscalants, sodium bisulfite for dechlorination).

- Chlorine removal to protect sensitive membranes.

- Biofilm preventionthrough periodic shock treatment.

- Low-maintenance, high-efficiency disinfection systems.

Real-Time Instrumentation & Monitoring

Features:

- Online sensors (pH, conductivity, ORP, turbidity, flow).

- Continuous pressure and flow monitoring at critical points.

- Automated alerts for parameter deviations.

- Data export for regulatory compliance and reporting.

- Redundant sensors ensuring fail-safe operation.

Smart Automation & Control Optimized

Features:

- PLC-based automation (full/semi-auto/manual modes).

- SCADA/HMI integration for seamless remote operation.

- Instant alarms for pressure, flow, or quality anomalies.

- Customizable control logic for process flexibility.

- Audit trails for operational transparency and traceability.

Regulatory Compliance & Documentation

Features:

- Compliant with cGMP, FDA, ISPE, and ISO standards.

- USP– Class VI and FDA CFR 21-certified materials.

- Full FAT/IQ/OQ/PQ validation support.

- Detailed component and system documentation.

- Environmental and safety adherence (ISO 14001, OSHA).

Low-Maintenance & CIP-Ready Design

Features:

- Easy-access components for quick servicing.

- Automated backwash and regeneration cycles.

- CIP compatibility for thorough cleaning.

- Modular design for minimal downtime.

- Predictive maintenance alerts for proactive servicing.

Key Features :

Reliable and Robust

System is designed to handle wide range of raw water quality fluctuations

Built in Safety and Controls

Safety features to ensure the life and performance of the sensitive membranes in the downstream

Automated and Easy to Operate

The system is automated to eliminate human errors by incorporating auto multiport valve, auto backwashing systems etc.

Quality Equipments

We use only high quality products like Norit / Inge / Dow UF membranes, Pentair vessels and multiport valves, Grundfos pumps etc.

COMPONENT-WISE SYSTEM DESCRIPTION READ MORE...

1. Multigrade Sand Filter (MGF)

Multigrade Sand Filter (MGF)

Primary filtration barrier to remove suspended solids and reduce turbidity.

- Layered media for effective particle capture

- Automatic backwash cycles for ease of maintenance

- Turbidity sensor for performance monitoring

2. Activated Carbon Filter (ACF)

Activated Carbon Filter (ACF)

Removes chlorine, organic compounds, color, odor, and improves taste.

- Dechlorination for membrane protection

- TOC reduction for compliance with WFI standards

- Automatic backwash and regeneration

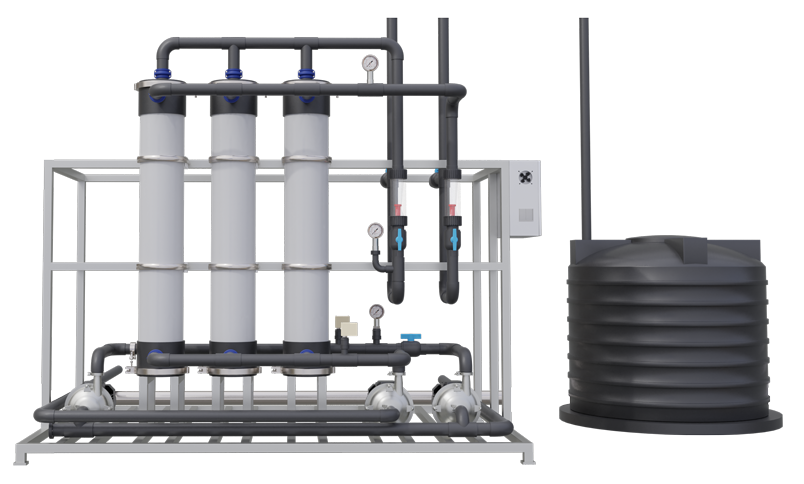

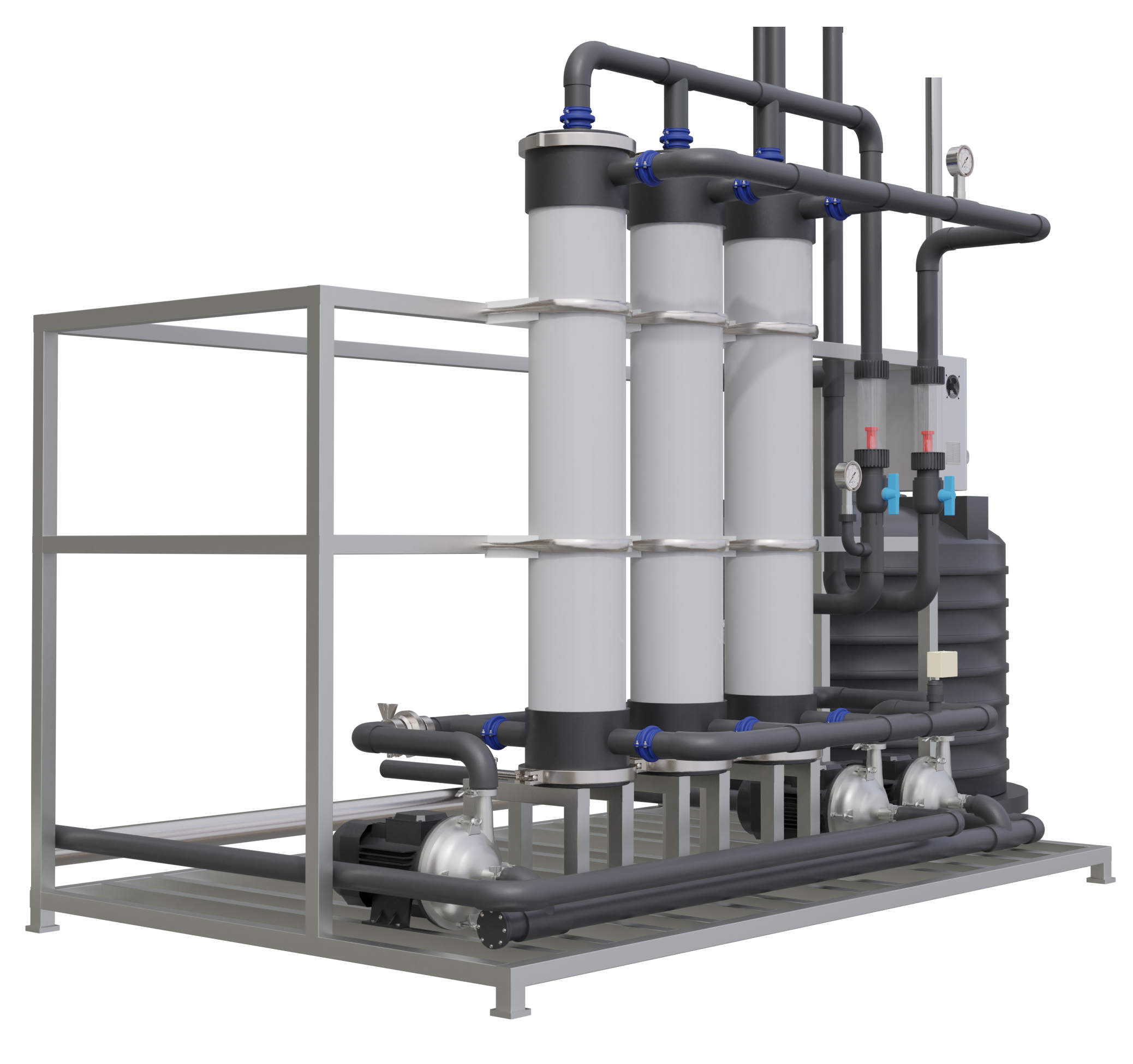

3. Ultrafiltration System (UF)

Ultrafiltration System (UF)

Removes fine particles, colloids, and microbiological contaminants.

- SDI consistently <5 to protect RO membranes

- Fully automated CIP, backwash, and rinse cycles

- Skid-mounted, compact design for plug-and-play integration

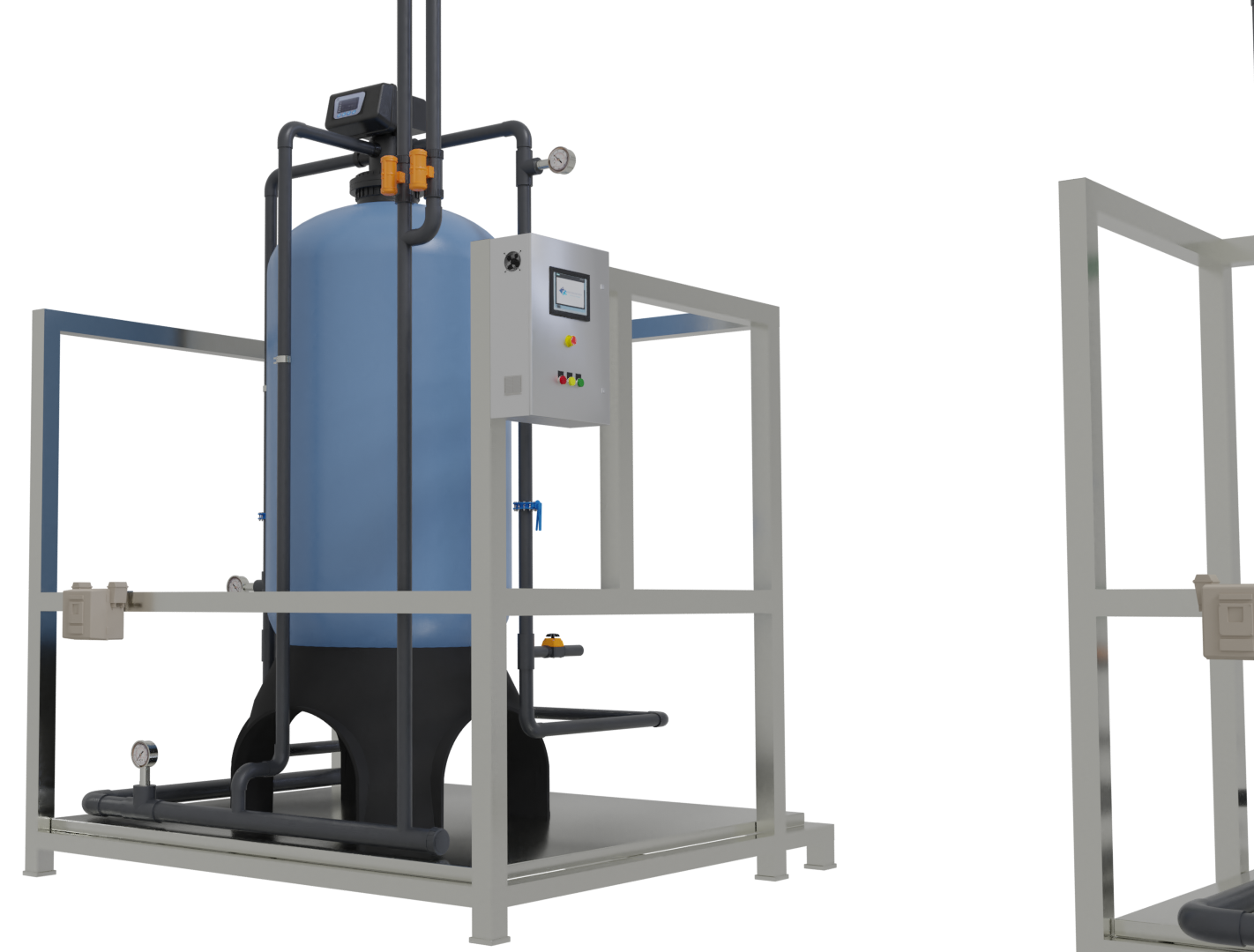

4. Duplex Water Softener

Duplex Water Softener

Reduces water hardness by eliminating calcium and magnesium ions.

- Dual resin beds for uninterrupted operation.

- Auto regeneration and backwash via brine dosing.

- Hardness monitoring sensor as an option.

5. Iron Removal Filter

Iron Removal Filter

If iron or manganese levels are high in the raw water.

- Catalytic media or oxidation dosing used.

- Prevents membrane fouling and equipment scaling.

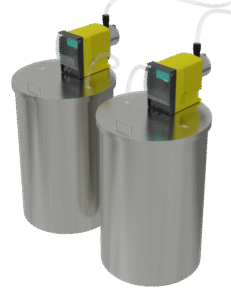

6. Antiscalant Dosing System

Antiscalant Dosing System

Prevents scaling in downstream RO membranes.

- Auto-adjust dosing based on flow.

- Dosing of FDA/NSF-approved chemicals.

7. pH Correction / Chemical Dosing System

pH Correction / Chemical Dosing System

Ensures feed water pH is within optimal range for downstream processing.

- Acid/alkali dosing to correct pH.

- Equipped with pH sensor, controller, and dosing pump.

8. Chlorination / De-chlorination Unit

Chlorination / De-chlorination Unit

Depending on the microbial profile of raw water.

- Chlorine dosing for microbial control.

- Sodium metabisulfite dosing for dechlorination before RO

9. Cartridge / Micron Filtration

Cartridge / Micron Filtration

Final step before RO or other purification stages.

- 5-micron or 1-micron filters for polishing filtration.

- Replaceable cartridges with high dirt-holding capacity.

Ultrafiltration System

Almost every RO membrane in the downstream demands the SDI to be less than 5 and hence UF ensures this consistently. Our UF is designed to be fully automated with backwash, CIP, rinsing cycles being triggered automatically either by time or by differential pressure. We also use UF membranes from manufacturers of repute like INGE, NORIT, DOW etc.

- Skid Mounted, Plug and Play System

- Fully Automated CIP, Backwash, Rinse Cycles

- UF Membranes from Dow, Norit, Inge Etc.

- Smart Operation and Controls

- High Performance and High Life of Membranes

Duplex Softener

The duplex softener removes dissolved calcium and magnesium from the water making it soft water. It comprises two resin columns to reduce downtime. When the first column reaches exhaustion the second column treats water while the first column undergoes regeneration.

- Fully Automatic

- Compact, Modular Design

- Easy Backwashing

Automated Dosing System

Our automated dosing system maintains desired pH level in the water storage tank. It helps protect corrosion and precipitation.

- Auto Flow Adapt Function

- Accurate and Reliable

- Simple Operations

Multigrade Sand Filter

Multigrade sand filter is used at the initial stage to treat feed water. It removes suspended particles using a media mix.

- Maximum Recovery

- Efficient Design Ensures High Performance

- Easy to Operate and Maintain

Why This System?

- Protects Membranes – Reduces fouling and scaling to extend RO/UF lifespan.

- Handles Variability – Stable performance even with changing water quality.

- Meets Strict Standards – Compliant with FDA, cGMP, and ISO requirements.

- Prevents Downtime – Real-time monitoring and automated controls.

- Saves Costs – Efficient operation lowers chemical and energy use.

- Easy to Scale – Modular design grows with your needs.

- All-in-One Solution – Covers disinfection, filtration, and contamination control.

Projects Executed

Our Portfolio

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!