Process Vessels

Product Description

For the Pharmaceutical and Bio-pharmaceutical industries, Pavitra delivers high quality process vessels that enable the maintenance of optimal product temperature efficiently.

Pavitra has the infrastructure and capability to design, engineer, and fabricate very large and most complex processing vessels and equipment for the pharmaceutical and Bio-pharmaceutical industry. We also engineer automation to precisely control the process parameters, delivering the highest yield while reducing the consumption of utilities (WFI, PWS, Clean-Steam, Cleaning Media etc.). Our systems also deliver the highest lifecycle value.

Key Features

Material of Construction

Features:

- SS316L stainless steel - with ultra-low carbon content for superior corrosion resistance.

- Aggressive chemicals – Hastelloy, glass-lined steel, or polymer-lined materials.

- Electropolished interiors – (Ra ≤ 0.4 µm) for hygienic, non-contaminating surfaces.

- Passivation treatment – to enhance oxide layer and prevent rust.

- USP Class VI and FDA-compliant – materials for pharmaceutical safety.

Design Standards

Features:

- Compliant with – ASME BPE (BioProcessing Equipment) for biopharma applications.

- Meets Requirements – of FDA 21 CFR Part 210/211 and EU GMP Annex 1.

- Pressure-rated per – ASME Section VIII and PED 2014/68/EU.

- Certified manufacturing –USP Class VI and ISO 9001:2015.

- 3D design validation – via FEA (Finite Element Analysis) for structural integrity.

Sanitary Construction

Features:

- Orbital welding – for seamless, crevice-free joints (per ASME BPE standards).

- Tri-clamp (Sanitary) fittings – for quick, aseptic disassembly.

- Designed – to be fully drainable with a sloped bottom (≥2° slope).

- CIP/SIP-ready – with spray balls and steam-jacketed options.

- Zero dead-leg – geometry to prevent microbial harborage.

Temperature & Pressure Control

Features:

- Jacketed design - (steam/thermal oil) for precise temperature uniformity.

- PT100/RTD sensors – for real-time monitoring ±0.5°C accuracy.

- Pressure-rated up to 10 bar – (customizable for high-pressure reactions).

- Explosion-proof – options for volatile solvent handling.

- Validated thermal mapping – for compliance with ICH Q7 guidelines.

Agitation & Mixing

Features:

- Variable-speed drives – (0–300 RPM) with PTFE-coated impellers.

- Magnetic coupling –for leak-free operation.

- API homogeneity – for High-shear or low-shear mixing.

- Load cells – for batch weight accuracy (±0.1%).

- ATEX-certified – motors for hazardous areas.

Automation & Compliance

Features:

- PLC/SCADA integration – with 21 CFR Part 11-compliant software.

- Data logging – for full audit trails and electronic batch records.

- PAT – (Process Analytical Technology) compatibility.

- validation protocols – for OQ/PQ.

- Remote monitoring – via IoT-enabled sensors.

Why This System?

- Regulatory Assurance: – Fully compliant with FDA, EMA, and WHO-GMP standards.

- Future-Proof Design: – Scalable for continuous manufacturing and Industry 4.0 integration.

- Risk Mitigation: – Validated cleaning (CIP/SIP) and material traceability.

- Efficiency Boost: – Reduced downtime via modular, quick-change components.

- Global Acceptance: – Certified for US, EU, and emerging markets.

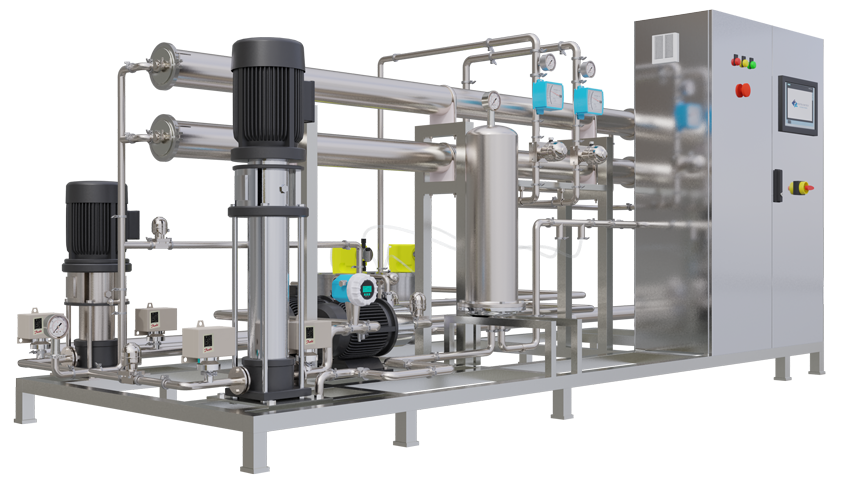

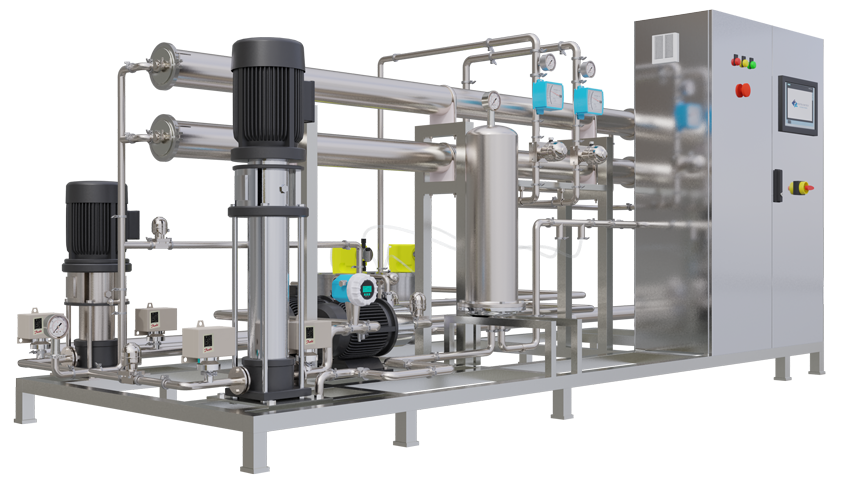

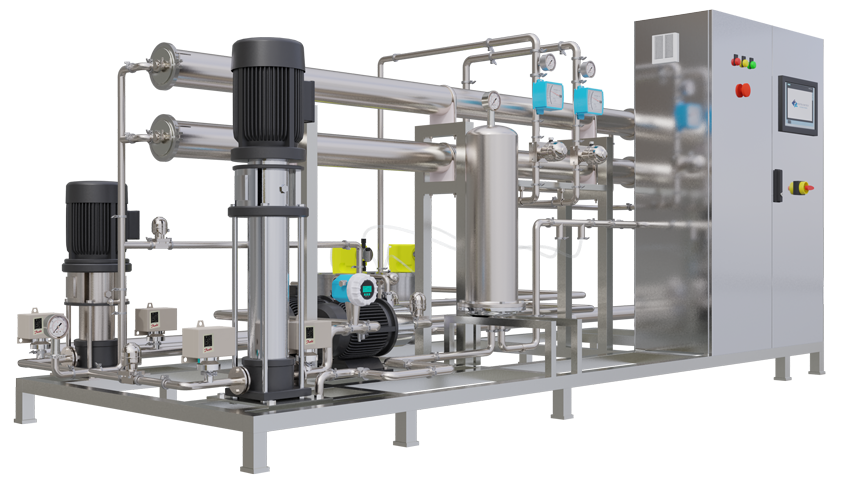

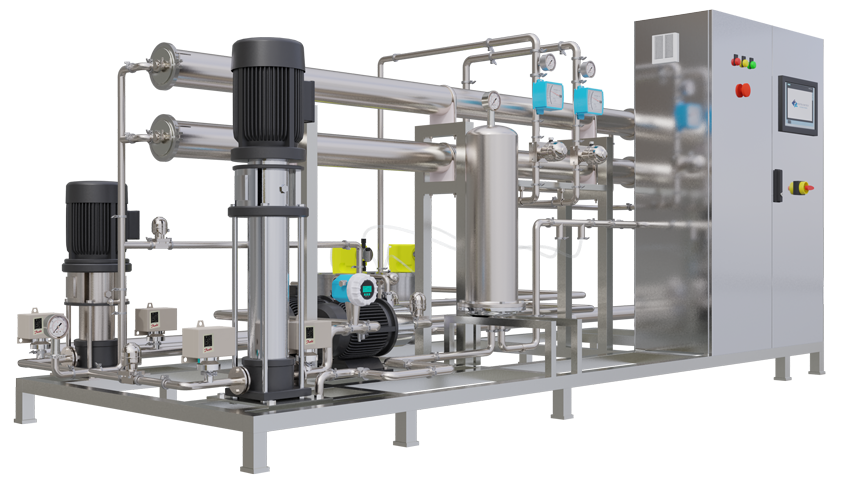

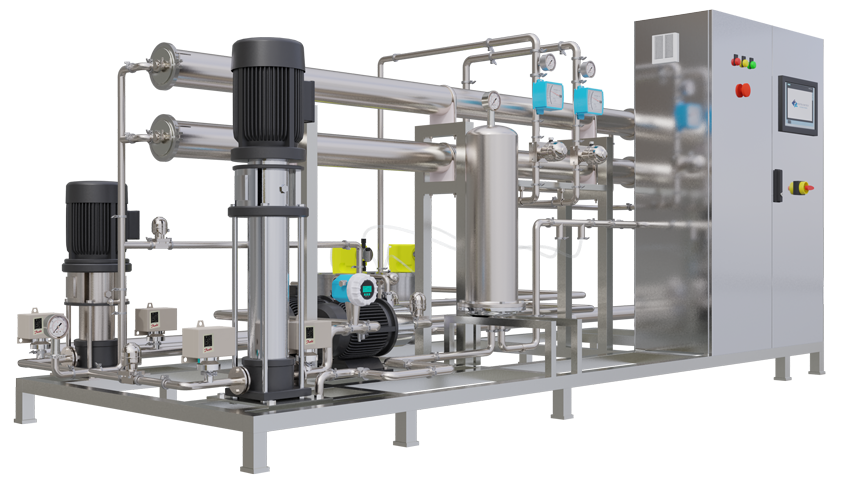

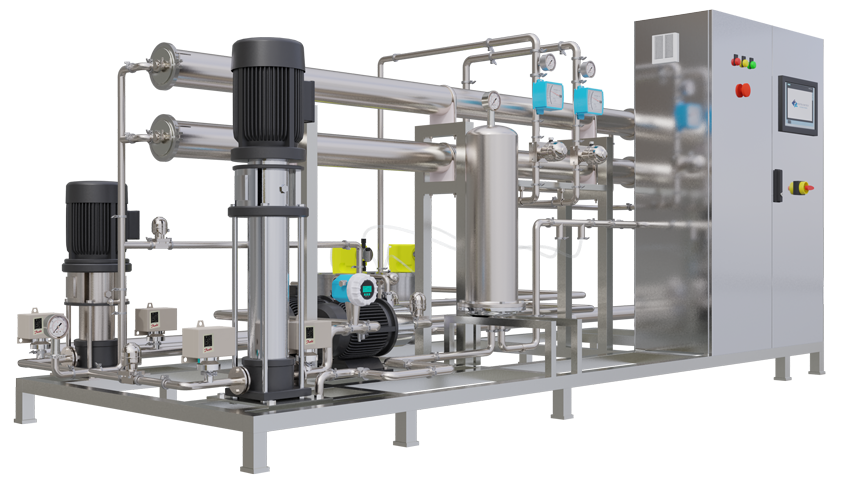

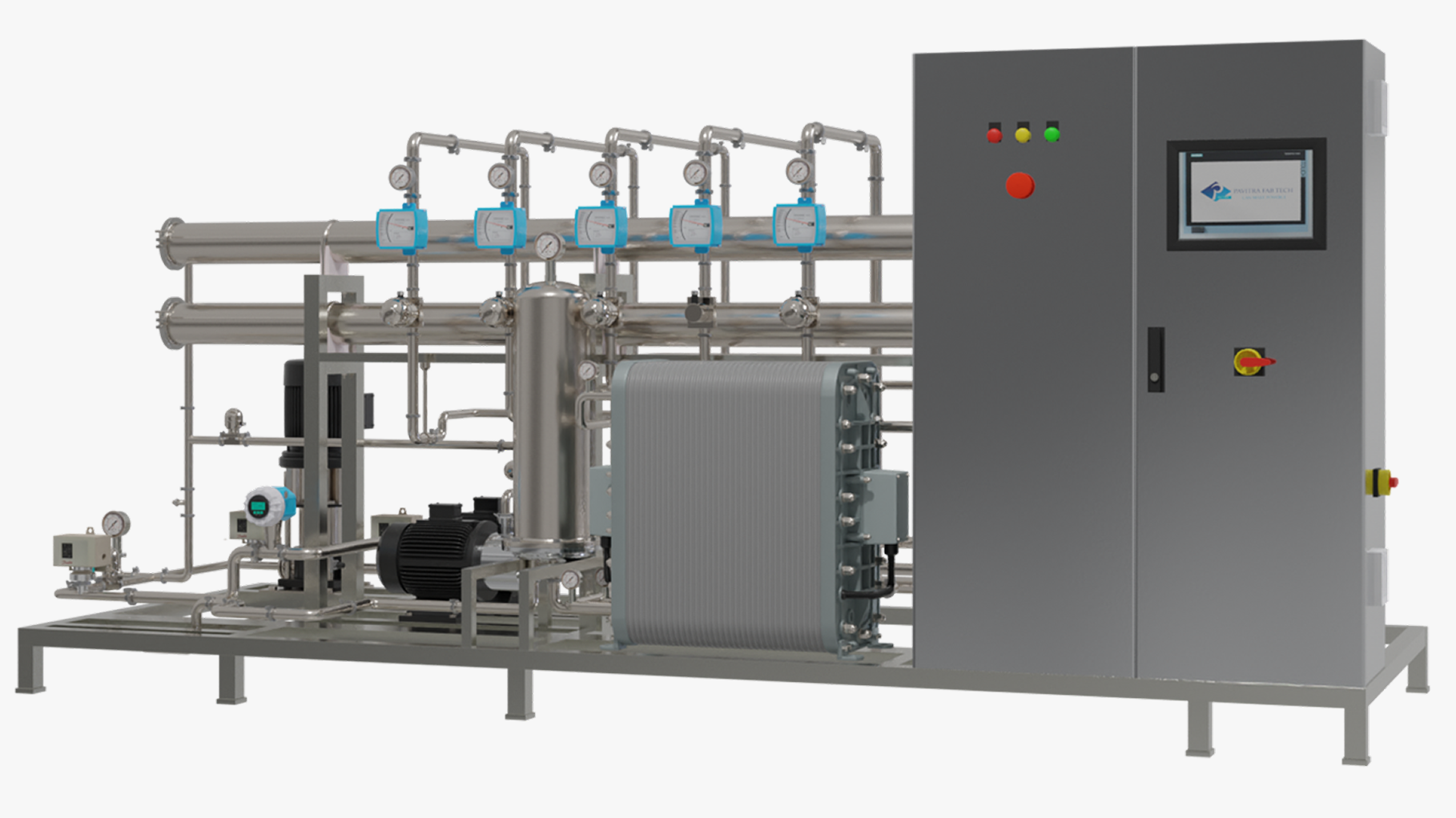

Key Features :

RO Membrane

High recovery, high rejection membranefrom the best manufacturers in the world

In-situ CIP / SIP

Integrated with in-situ CIP and sanitization in both Auto / Manual configuration

Reliable HP Pump

Grundfos SS316L, High Pressure, heavy duty pump with standby

The Controls & Systems

Fully automated, with ORP analyzer and other safety an control features

Projects Executed

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 360 degree spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Our Portfolio

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!