Sanitary Piping

Sanitary Piping

Product Description

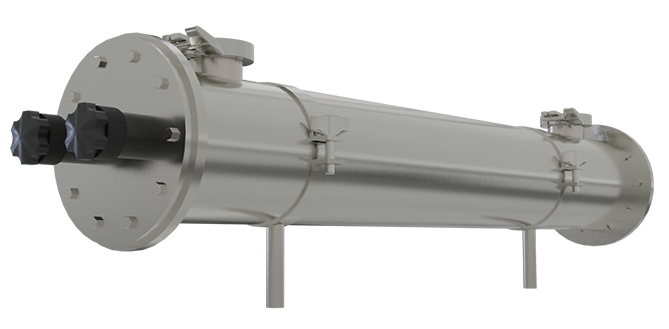

SS316L sanitary piping is the gold standard for high-purity fluid transport in pharmaceutical, biotech, and food-grade applications. Designed for Purified Water (PW), Water for Injection (WFI), Clean Steam, and process fluids, it ensures zero contamination, regulatory compliance, and long-term reliability.

Key Features

Material Composition

Features:

- Stainless Steel 316L (low-carbon variant) for superior corrosion resistance.

- 2–3% molybdenum content – enhances resistance to chlorides and acids.

- Ultra-low carbon (≤0.03%) – prevents carbide precipitation (sensitization).

- High chromium (16–18%) – for passive oxide layer formation.

- Certified melt chemistry – with full material traceability (EN 10204 MTC 3.1).

Sanitary Surface Finish

Features:

- Electropolished interior – (Ra ≤ 0.4 µm or better) minimizes microbial adhesion.

- Exterior mechanically polished – (Ra ≤ 0.8 µm) for clean-ability.

- Passivation – (nitric or citric acid) ensures corrosion resistance.

- Non-porous, crevice-free surfaces – prevent biofilm formation.

- Validated cleaning protocols – for FDA/EMA compliance.

Hygienic Sanitary Design

Features:

- Orbital-welded joints – with full penetration and purge gas backing.

- Tri-clamp (DIN 32676/ASME BPE) – fittings for rapid disassembly.

- Zero dead-leg valves & fittings – eliminate stagnant zones.

- Self-draining slopes – (1:100 minimum) for complete fluid evacuation.

- Diaphragm-sealed valves – for sterile isolation.

Regulatory Compliance

Features:

- ASME BPE (BioProcessing Equipment) standards for biopharma.

- Compliance – FDA 21 CFR, EU GMP, USP <661> & USP Class VI

- DIN 11850 & EN 10357 – (European sanitary piping standards).

- ISO 9001/13485 –certified manufacturing.

- Material test reports (MTC 3.1) – for full traceability.

Precision Installation & Quality

Features:

- Orbital welding with full documentation – (Ra ≤ 0.4 µm or better) minimizes microbial adhesion.

- Borescope inspection (per ASME BPE) – for weld integrity.

- Examination – Helium leak testing & Dye-penetrant.

- Vibration-Resistant – supports with thermal expansion flexibility.

- Post-installation – cleanability validation (CIP/SIP compatible).

Customizable

Features:

- Temp control – with oInsulated (PIR/Armaflex) or heat-traced (steam/electric).

- Validatable – for FDA/EMA audits with full FAT/DQ/IQ/OQ/PQ support.

- High-purity orbital welding – for oxygen-sensitive systems.

- Scalable – for large PW/WFI loop distribution.

- Compatible – with single-use bioprocessing connections.

Why This System?

- Prevents contamination – in WFI, PW, and process fluids – critical for sterile manufacturing.

- Meets global standards – (FDA, EU GMP, ASME BPE) for audit-ready compliance.

- Reduces downtime – with quick-disconnect fittings and CIP/SIP compatibility.

- Extends service life – with corrosion-resistant 316L and passivation.

- Ensures product safety – in pharma, biotech, food, and cosmetics.

Key Features :

- Corrosion Resistance – Stainless steel, PVC-CPVDF, or lined pipes for longevity.

- Smooth Interior Surface – Reduces bacterial adhesion and ensures easy cleaning.

- Leak-Proof Joints – Sanitary clamps, orbital welding, or tri-clamp fittings.

- Compliance with Standards – ASME BPE, FDA, cGMP, and ISO requirements.

- Modular & Scalable Design – Allows easy expansion and maintenance.

Product Description

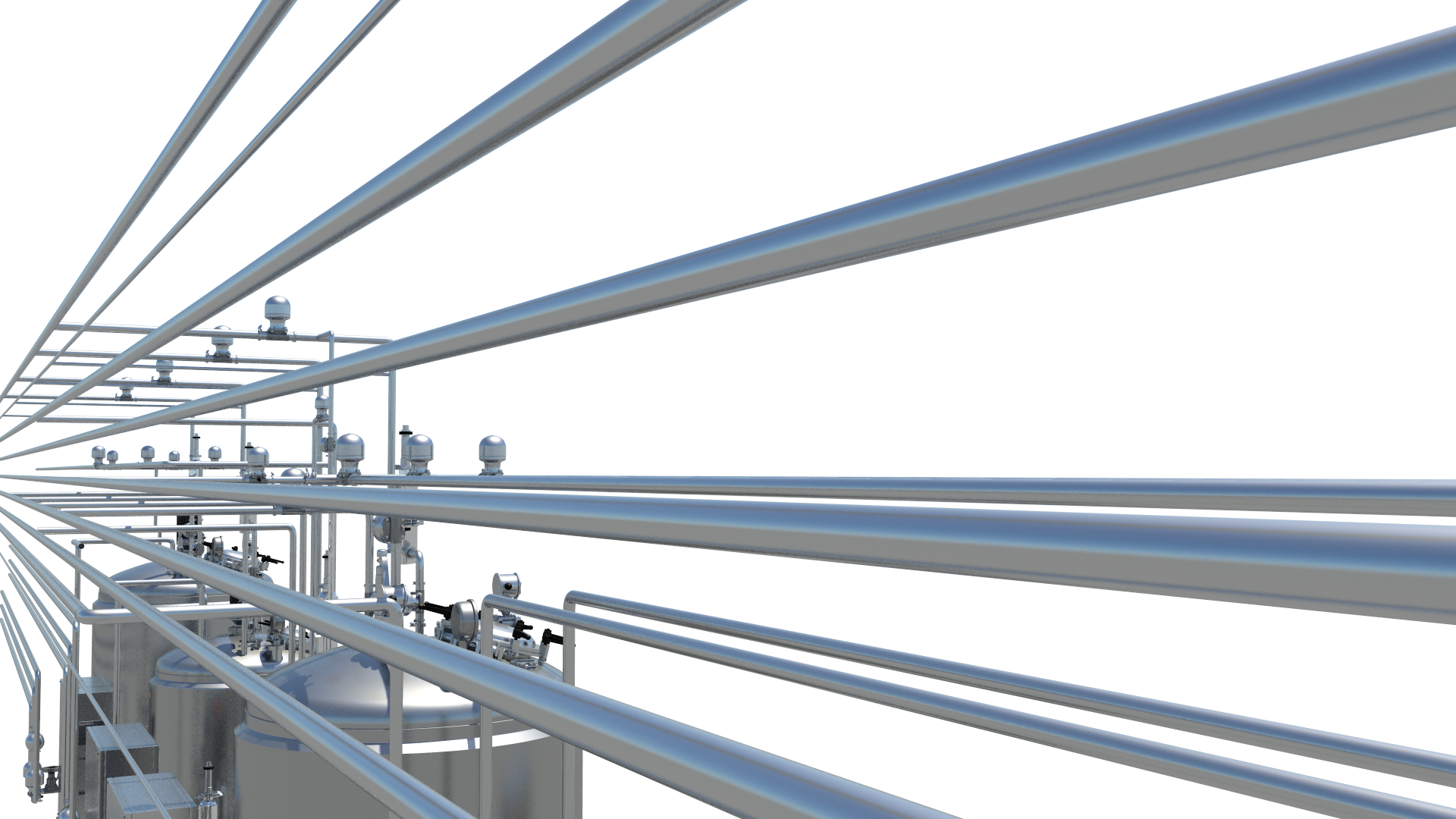

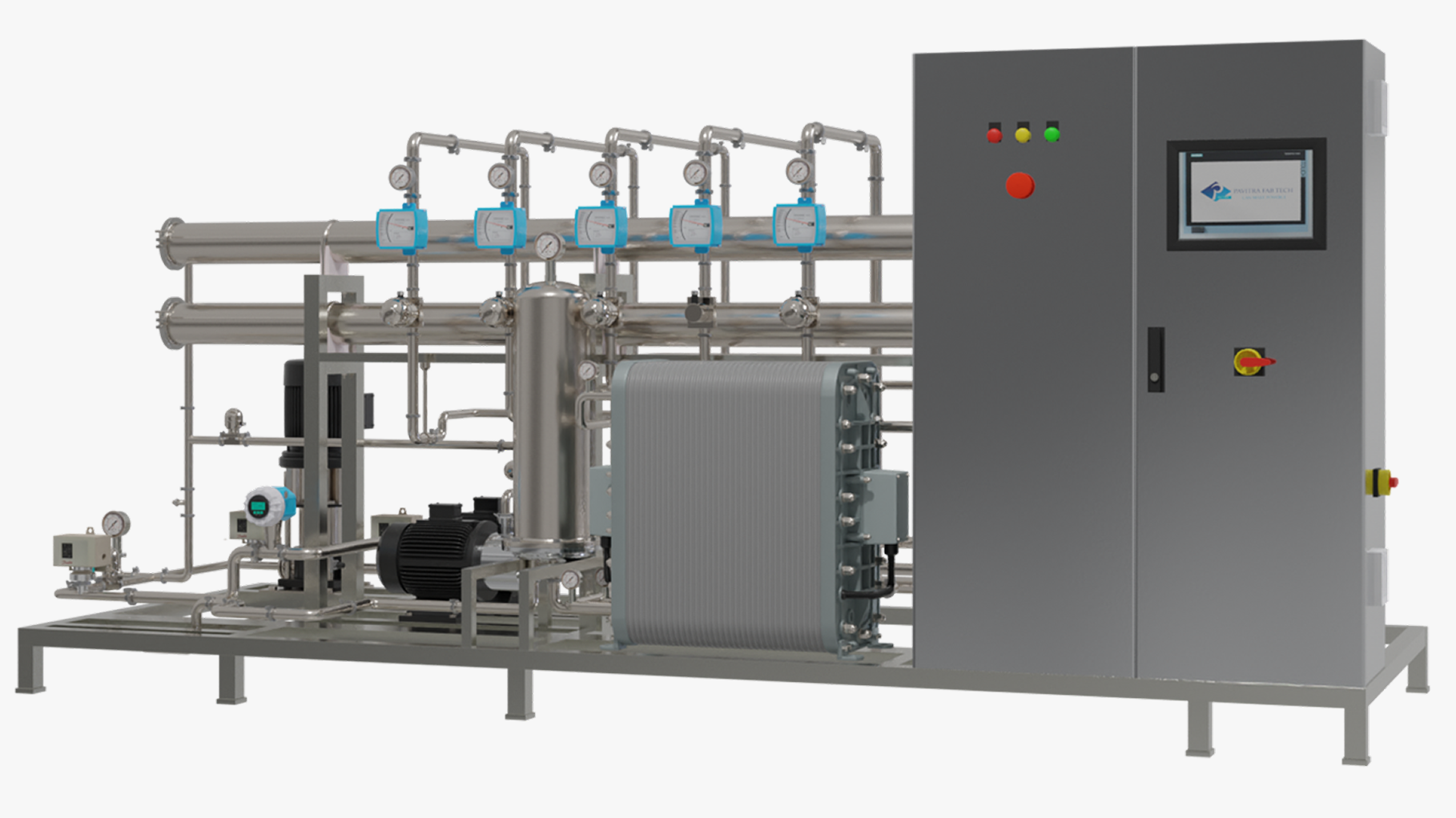

Water and sanitary piping systems are critical components in industries where hygiene, contamination control, and efficient fluid transportation are essential. These systems ensure the safe and reliable transfer of water, chemicals, and waste materials while maintaining strict compliance with industry standards.

In sectors like pharmaceuticals, food & beverage, biotechnology, and chemical processing, the quality of piping systems directly impacts product safety, operational efficiency, and regulatory compliance. Choosing the right materials, design, and maintenance practices is crucial to prevent contamination, corrosion, and system failures.

Design & Engineering

Efficient system design, with minimal pressure drops, right pump selection, VFD for power efficiency and high quality materials and surface finish to ensure bacteriostatic condition.

High Reliability

System designed for consistent performance, high reliability and low maintenance.

Instrumentation & Control

Precision & high quality instruments that are reliable, Monitoring of critical parameters with data logging with GAMP 5 and 21 CFR Part 11 compliance

In build features

System designed for in-situ hot water sanitization with precise steam control.

Projects Executed

Our Portfolio

Schedule a Meeting

Need a customized solution for your industry? Contact us today for expert design and implementation!

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!